Introduction

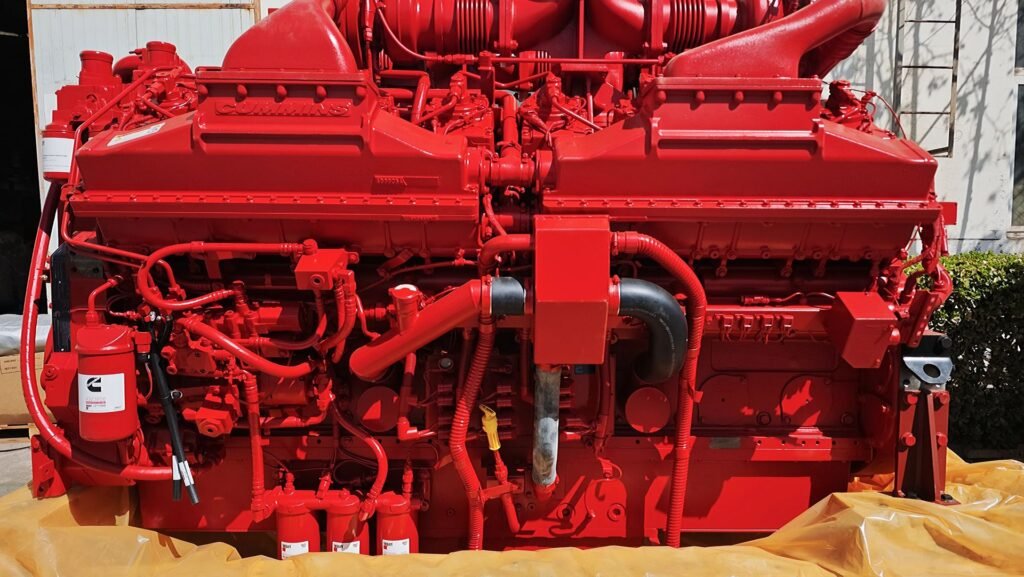

When it comes to ensuring uninterrupted power for critical operations—from hospitals to data centers—following Cummins generator set maintenance best practices is non-negotiable. Cummins gensets are globally trusted for durability, reliability, and robust performance, but even the most well-engineered machines depend on proactive care. Below are the golden rules to keep your generator set running at peak efficiency, avoid costly downtime, and protect your power investment for years to come.

In the world of critical power, few names command as much respect as Cummins. Synonymous with durability, reliability, and robust performance, Cummins generator sets are the backbone of hospitals, data centers, industrial complexes, and emergency services worldwide. However, even the most impeccably engineered machine is only as reliable as the maintenance and operation practices it receives.

Proactive care is not just a recommendation; it is the single most critical factor in ensuring your Cummins genset answers the call during a power outage. By adhering to these time-tested maintenance and operation practices, you can maximize the lifespan, efficiency, and unwavering reliability of your power investment.

1. The Non-Negotiable: Pre-Operation Inspection

Before every scheduled test run and certainly before any potential deployment, a thorough visual and systems check is paramount. This habit prevents minor issues from escalating into catastrophic failures.

- Visual Inspection: Check for any signs of leaks (oil, fuel, coolant), loose bolts, or damaged wiring.

- Fluid Levels: Verify that engine oil, coolant, and fuel levels are within the prescribed ranges (refer to the official Cummins engine owner’s manual for model-specific specs).

- Air Intake & Exhaust: Ensure the air filter is clean and the exhaust path is unobstructed.

- Area Clearance: Confirm the area around the generator is clear of debris, flammable materials, and has adequate ventilation.

2. The Lifeblood: Adhering to Oil and Filter Change Schedules

Engine oil is the lifeblood of your Cummins genset. It lubricates, cleans, cools, and protects internal components from wear. Adhering to a strict oil and filter change schedule based on operational hours, as outlined in your owner’s manual, is non-negotiable.

- Use the Correct Oil: Always use the recommended oil grade and type (e.g., CJ-4, CK-4) specified by Cummins for your specific engine model and ambient conditions.

- Change Filters Concurrently: Never change the oil without also replacing the oil filter, fuel filters, and air filter as per the service schedule. A new oil filter is essential to trap contaminants and protect the freshly introduced oil.Learn more about genuine Cummins filters for optimal performance.

3. Keeping Cool: Cooling System Maintenance

A significant percentage of generator failures are cooling system-related. Proper maintenance prevents overheating, which can cause severe engine damage in minutes.

- Coolant Level and Quality: Regularly check the coolant level in the overflow tank. More importantly, test the coolant mixture periodically for proper concentration (typically a 50/50 mix of water and ethylene glycol) and additive strength. Cummins’ proprietary coolant filters contain Supplemental Coolant Additives (SCAs) that replenish the corrosion-inhibiting properties of the coolant.

- Radiator and Hoses: Keep the radiator’s external fins clean from dirt, dust, and debris. Inspect coolant hoses for signs of cracking, bulging, or softening and replace them proactively.Explore our Cummins cooling system maintenance kits.

4. The Starting Point: Meticulous Battery Care

The most common reason for a generator failing to start is a weak or dead battery. Your Cummins genset can be in perfect mechanical condition, but without a reliable battery, it is powerless.

- Terminal Cleaning: Keep battery terminals clean and tight to prevent voltage drop and starting issues. A coating of anti-corrosion spray is highly recommended.

- Voltage and Specific Gravity: Regularly test the battery’s voltage and specific gravity (for flooded lead-acid batteries). Maintain the batteries with a quality smart charger or float charger to keep them at peak charge and prevent sulfation.

- Load Testing: Perform regular battery load tests as part of your annual maintenance to assess the battery’s ability to deliver cold cranking amps (CCA) under load.Contact us and we will provide compatible Cummins generator batteries

5. Burning Off the Glaze: The Critical Role of Load Bank Testing

A generator running lightly or at no load for extended periods suffers from “wet stacking”—a condition where unburned fuel and soot accumulate in the exhaust system. More critically, the engine does not reach its optimal operating temperature, leading to carbon buildup on injectors, rings, and valves.Load bank testing is the definitive solution. This process applies an artificial, measurable electrical load to the generator, forcing it to operate at or near its rated capacity for a sustained period. The benefits are profound:

- Burns off accumulated carbon and fuel deposits.

- Verifies that the genset can produce its nameplate-rated power (kW and kVA).

- Validates the performance of the engine, alternator, and voltage regulator under real-world conditions.Annual load bank testing is a best practice for any standby generator.Connect with a certified Cummins service provider for professional load bank testing.

6. Fuel for Thought: Fuel System Inspection & Cleaning

Diesel fuel is susceptible to contamination from water, algae (microbial growth), and sediment. A compromised fuel system is a primary cause of poor performance, hard starting, and injector failure.

- Water Separation: Drain water from the primary fuel filter/water separator regularly.

- Fuel Polishing: For long-term fuel storage, consider a fuel polishing system that continuously filters and recirculates the fuel in the tank to remove water and particulates.

- Biocide Treatment: If microbial growth is suspected, use an EPA-approved biocide to eliminate the bacteria and fungi that clog filters and corrode tanks (follow EPA’s diesel fuel contamination guidelines for compliance).

- Injector Service: Follow Cummins’ recommended service intervals for fuel injector inspection and testing.

Other Essential Maintenance & Operation Practices

Beyond the core areas, several other practices contribute to legendary generator reliability.

- Regular Unloaded Exercise: Schedule the generator to run for 20-30 minutes weekly, preferably under load, to circulate fluids, keep seals lubricated, and burn off minor moisture.

- Air Filter Maintenance: Monitor the air filter restriction gauge. Replace the primary and secondary air filters as needed. Operating with a clogged air filter reduces power and increases fuel consumption.

- Belt Tension Inspection: Check the tension of fan and accessory drive belts. Belts that are too loose can slip and cause overheating; belts that are too tight can cause premature bearing failure.

- Comprehensive Record Keeping: Maintain a detailed log of all maintenance activities, run hours, fault codes, and repairs. Ask us for a free Cummins maintenance log template to streamline tracking.

- Professional Support: While daily checks can be handled in-house, partner with a certified Cummins distributor or service provider for scheduled major services and complex diagnostics. Their technicians have the specialized tools, training, and access to genuine Cummins parts.

Explore our full range of Cummins generator sets and learn how proper maintenance enhances their value.