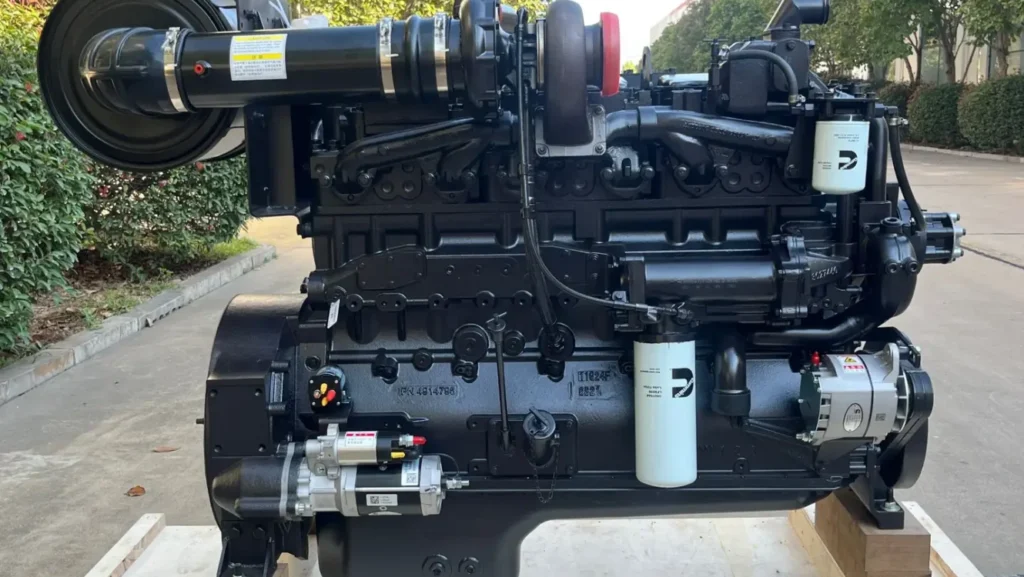

Sudden Cummins generator failures can disrupt operations and cause costly downtime. That’s why learning basic Cummins generator troubleshooting skills is essential for every owner. Below, we break down 3 of the most frequent faults, sorted by Cummins engine structural characteristics, with simple, step-by-step self-check solutions. You’ll avoid waiting for after-sales and resolve minor issues quickly—saving time and money.

Rapid troubleshooting of sudden generator set failures can reduce downtime losses. We share 3 common faults most frequently encountered by customers and their solutions, sorted out based on the structural characteristics of Cummins engines, which are simple and easy to operate:

Fault 1: The Unit Fails to Start

Check these common causes in priority order:① Battery depletion: Use a multimeter to measure voltage (normal ≥12V). Charge the battery with a quality charger or replace it if worn out. Refer to Cummins battery maintenance guidelines for proper care.② Insufficient fuel/clogged oil circuit: Check the fuel tank level. If the unit has been idle for a long time, replace old fuel (to avoid deterioration) and clean the fuel filter. Order genuine fuel filters from our Cummins maintenance parts store.③ Faulty start switch: Inspect the switch for loose contact and check if the fuse is blown—replace it with a fuse of the same specification.

If the above checks don’t work, contact GoCummins after-sales service for on-site support within 4 hours.

Fault 2: Insufficient Power During Operation (Can’t Drive Load)

Solve the issue with these steps:① Clogged air filter: Remove the filter for cleaning (paper filters must be replaced) to ensure unobstructed air intake. A dirty filter restricts airflow and reduces power—regular replacement is key. Learn more about air filter maintenance in our Cummins generator daily maintenance guide.② Insufficient fuel supply: Check the fuel pump pressure and clean impurities from the oil circuit. Use fuel polishing if long-term storage causes contamination.③ Engine governor failure: This requires professional debugging. Cummins original governors are highly precise—do not disassemble them yourself. Book GoCummins professional technical support for governor calibration.

For additional power-related troubleshooting, refer to Cummins official performance troubleshooting manual.

Fault 3: Abnormal Noises (Knocking/Roaring) During Operation

This is a dangerous signal—shut down the unit immediately for inspection:① Low oil level: Add genuine Cummins engine oil (meets CJ-4 standards) to avoid cylinder scuffing from insufficient lubrication. Never use non-genuine oil—read our consumables guide for details.② Worn generator bearings: Listen to locate the noise (front/rear end) and contact after-sales to replace bearings with genuine parts. Explore our genuine Cummins bearings.③ Carbon deposits in the cylinder: Long-term low-load operation causes carbon buildup. Run the unit at high load once every 3 months or use original Cummins carbon deposit cleaner. Learn about load bank testing benefits in our maintenance best practices.

For safety tips during troubleshooting, check Energy.gov’s generator safety guidelines.

Tip

If the fault involves the engine’s internal structure (e.g., cylinder block, crankshaft), do not disassemble it yourself. GoCummins after-sales teams have genuine Cummins maintenance equipment and trained technicians to quickly locate problems—minimizing downtime.

For complex faults or annual inspections, rely on our certified Cummins service providers and review our warranty policy to ensure coverage for genuine parts and repairs.