As a global pioneer in power technology, Cummins is committed to “driving the world forward and achieving the most beautiful life”. Since 1919, the company has been innovating to provide solutions that drive people, products, and economies.

Our five business segments – Engines, Components, Distribution, Powertrains, and Cummins Accelera™ – have a broad portfolio of products including advanced diesel, alternative fuels, electric and hybrid powertrains; integrated power system; Key components such as aftertreatment systems, turbochargers, fuel systems, control systems, transmissions, axles, and braking systems; and zero-emission technologies such as batteries and electric powertrain systems and electrolyzers. With a global footprint, deep technical expertise and extensive service network, we provide our customers with reliable, cutting-edge customized solutions and support them in their energy transition through the “Zero Carbon Goals” strategy. We create value for our customers, investors, and employees, and empower our communities through our three pillars of corporate responsibility: education, equal opportunity, and environmental protection.

Headquartered in Columbus, Indiana, Cummins employs approximately 70,000 people worldwide, with sales of $34.1 billion and revenue of $3.9 billion in 2024.

Cummins Corporation consists of five business units that are both independent and complementary Engine Division

Engine Division

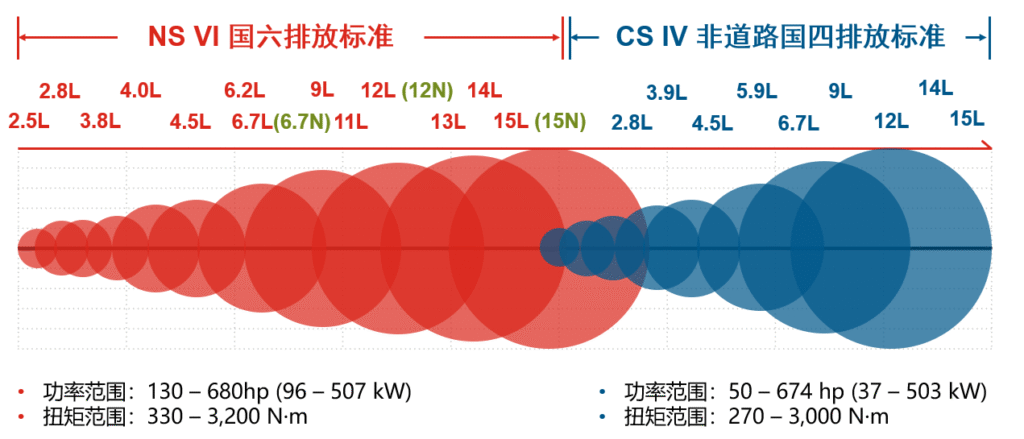

The Engine Division is Cummins’ earliest and core business. After more than 100 years of continuous development, it currently focuses on the research and development, production and sales of 2.5L to 15L diesel, natural gas, as well as a variety of alternative fuels and new energy engine products including hydrogen energy, which are widely used in a variety of application scenarios on and off the road, including medium and heavy trucks, buses, light commercial vehicles, pickup trucks and special special vehicles, as well as off-highway fields such as construction machinery and agricultural machinery.

Cummins engines have always been known for their superior reliability, power and fuel economy, and have been leading the industry in meeting increasingly stringent road emissions (US EPA2021, Euro VI and China China VI) and off-road motor equipment emissions (Tier 5 interim/Stage IV).

In recent years, Cummins engine shipments have stabilized at more than 1.5 million units per year. China is one of Cummins’ most important markets in the world, and we have implemented a strategy to adapt to local markets and applications in China, and have 6 engine joint venture plants, which can customize product solutions for customers according to different markets and applications based on all of Cummins’ world’s most cutting-edge technology platforms.

Cummins engine type spectrum: 19 of Cummins’ 24 engine series have been locally produced in China

Power System Division

In 2016, Cummins merged its power business and high-horsepower business to form the Power System Division.

The High-Horsepower Engine segment focuses on high-power engines that power electric power, mining equipment, marine machinery, oil and gas fields, and railways. The products are widely used in mining, marine machinery, oil and gas fields, railways and construction machinery. The product line includes diesel engines (from 19 to 95 liters), gas engines (from 5.9 liters to 72 liters), drill generator sets and dual-fuel engines and components.

Cummins Power provides customers with power generation, conversion and control technologies and products worldwide, and is committed to meeting their power needs in the fields of continuous power generation, normal load, peak shaving, backup, cogeneration and turnkey projects of complete power plants. The product line includes diesel and alternative fuel generator sets (2.5kW ~ 2700kW), alternators (0.6 kVA ~ 30,000 kVA), engine engines, control systems, transfer switches (40 amps ~ 4,000 amps), and switchgear. The products are currently widely used in many industries such as data centers, telecommunications, finance, high-tech factories, medical, commercial, and leasing.

Distribution Division

Through Cummins’ global distribution service system, our specially trained service team provides 24/7 access to genuine parts, customer engineering, and expert support services for users around the world. Cummins’ service network covers more than 190 countries and regions around the world, with more than 500 distribution service outlets and more than 10,600 certified distribution outlets worldwide. Cummins’ wholly-owned network of distributors covers key markets around the world, including China, India, Japan, Australia, Europe, the Middle East and South Africa.

In China, the Distribution Division covers a total of 18 Cummins provincial customer support centers, as well as more than 3,000 authorized Cummins and joint venture distributors. As an important part of Cummins’ global service system, the partners of the distribution division have created a complete service network and regional support system, based on multi-line genuine parts and professional technical support, using digital cutting-edge means to provide customers with reliable, fast and intelligent one-stop service solutions to help customers succeed.

Parts Division

- Cummins has key components of the power chain, built in traditional energy and new energy advanced power chain integration technology.

- Cummins Engine Parts & Software Business:

- Cummins Turbocharging Technology System (formerly Holsett): Produces a full range of turbochargers and related products for diesel and natural gas engines above three liters, and at the same time looks forward to zero-carbon related fields, mainly used in the global commercial vehicle and industrial markets.

- Cummins Fuel System: Produces a full set of high-end diesel fuel common rail systems (including fuel pumps, fuel rails and injectors), provides industry-leading fuel system technology and product services for Cummins in China and global partners, and continues to tap the potential of traditional energy while actively deploying components in the multi-energy and zero-carbon fields.

- Cummins Gas Distribution Mechanism: Committed to the research and development and manufacturing of engine retarders, providing advanced engine retarding technology and solutions for commercial vehicle customers around the world, applied to medium and heavy-duty diesel and natural gas engines.

- Cummins Software and Electronics: Develops cutting-edge software and electronics for customers in commercial vehicles and industrial applications to help equipment operate with greater efficiency, performance, sustainability, and reliability.

- Cummins Emissions Treatment Systems: Develops and manufactures a wide range of emissions solutions and systems for light, medium, heavy, and high-horsepower commercial vehicles and construction machinery engines. Cummins emission treatment system can produce and integrate emission control systems such as oxidation catalytic converters, particle traps, and selective catalytic reducers; With rich practical application experience and early development capabilities, we provide complete integrated solutions for aftertreatment emission control systems for customers in China and around the world.

- Cummins Drive & Brake Systems: As a leading provider of advanced drive systems, brake systems, trailers, and aftermarket technologies, we provide customers with high-performance, efficient, and reliable solutions. Our Meritor® products are well recognized in the market.

- Cummins electric drive: The first electric drive system was born in 1995, and the first electric drive axle was born in 1998. Products include; Central drive motor solutions, electric drive axles, and a variety of main drive all-in-one power electronic products.

- Eaton Cummins: Committed to using cutting-edge automatic transmission technology to create a value-added experience for users. Eaton Cummins Win AMT has four core advantages: light, easy, economical and reliable, and is widely used in domestic comprehensive road condition transportation. Win AMT can be equipped with heavy-duty diesel and natural gas engines and supports matching hydraulic retarders. With advanced automatic transmission technology and services, we provide competitive solutions for users around the world.

New Energy Power Division

Cummins is an industry pioneer in multi-power solutions, designing, producing and distributing multi-energy power products including diesel and natural gas engines, hybrids, electric power, and fuel cells.

Cummins New Energy Power Division provides customers with system solutions for the whole industry chain of “production, storage and application” by actively laying out and developing technical capabilities in the field of hydrogen energy, designing and producing proton exchange membranes and solid-state oxide fuel cell systems and core components, as well as high-pressure hydrogen storage systems, electrolysis water hydrogen production equipment, megawatt-level hydrogen energy and multi-energy coupling solutions.

Cummins continues to innovate in zero-emission power, and its fuel cell technology powers a wide range of applications, including buses, trucks, rail transit, marine and power generation. At the same time, Cummins continues to explore energy decarbonization, and its proton exchange membrane and alkaline electrolysis water technology can be applied to various scenarios such as industrial manufacturing, chemical smelting, and renewable energy comprehensive solutions, helping the industry achieve the long-term goal of green decarbonization.

Rooted in China and create brilliance together

Cummins’ business ties with China began in 1975 when Mr. Irwin Miller, then chairman of Cummins, visited Beijing for the first time to seek business cooperation. In 1979, when China and the United States established diplomatic relations, China’s opening up to the outside world began, and the first Cummins office in China was established in Beijing.

In 1981, Chongqing Engine Plant began to license the production of Cummins engines, and in 1995, it jointly established a joint venture engine factory in China with Cummins.

So far, Cummins has a total of 37 institutions in China, including 26 manufacturing enterprises with more than 13,000 employees, producing engines, generator sets, alternators, turbocharging systems, emission treatment systems, fuel systems, hydrogen manufacturing, storage and fuel cells and other products. 18 provincial customer support centers, and more than 3,000 authorized Cummins and joint venture dealers.

Cummins has long insisted on forming strategic alliances with large Chinese enterprises to achieve common development. As the first foreign-funded diesel engine company to come to China for localized production, Cummins has established six engine joint ventures with leading Chinese companies including Dongfeng Motor, Chongqing Electromechanical, Shaanxi Automobile Group, Beiqi Foton, Liugong Group, and JAC Motor for more than 40 years, and 19 of Cummins’ 24 engine series have been produced locally in China.

In August 2006, Cummins and Dongfeng jointly established an engine technology R&D center in Wuhan, Hubei Province. In addition to developing the most suitable products for the Chinese market, Cummins China Technology Center is also expanding cooperation with Chinese partners in the field of research and development.

Cummins’ sales in China (including joint ventures) will be $6.5 billion in 2024, and China has become one of Cummins’ largest and fastest-growing overseas markets in the world.

After nearly 50 years of development, Cummins has become an integral part of China’s power industry, and has made its own contribution to the modernization of China’s engine industry through joint ventures, wholly-owned production and technology transfer.